25+

Years of Experience

UNITECH ENGINEERING

In a short span of time, UNITECH ENGINEERING has established a strong presence in the domestic market by consistently delivering quality-driven heat treatment solutions. The company’s mission is to design, develop, and implement customer-specific heat treatment facilities and equipment tailored to the evolving needs of the metals industry. With a strong focus on precision, durability, and customer satisfaction, UNITECH ENGINEERING continues to grow as a trusted partner in thermal engineering solutions.

Standard Furnaces & Vibro Finishing Machine

1. Box Type Hardening , Tempering & Annealing Furnace.

2. Bogie Type Furnace.

3. Forge Heating & Normalizing Furnace

4. Forced Air Circulation Furnace.

5. Aluminum Melting & Holding Furnace.

6. Laboratory Furnace.

7. All Kinds / Types of Furnace Spares

8. We Under Take all Types repair , modification & Lining Works

9. Vibro finishing Machine

10. Centrifugal Finishing Machine

11. Tube Type Vibratory Finishing Machine

12. Rotary Driers

13. Vibratory Separators

We request you to kindly consider us one of your positive suppliers for above equipments and services. We are confident that you will be fully satisfied by the performance of our products and will continue to place your valued orders with our company. Expecting your full support by sending your valued enquiries to us.

Precision-Engineered Thermal Solutions

Why Choose Us

Trusted by India’s leading manufacturing and automotive industries

What We Do

Requirements

Contact our engineering team for custom heat treatment solutions

Why Choose UNITECH ENGINEERING

Trusted by India’s leading manufacturing and automotive industries

Engineering Expertise

25+ years of specialized experience in furnace design and heat treatment technology with a team of skilled engineers

- Experienced design team

- Technical innovation

- Industry knowledge

Quality & Safety Focus

Rigorous quality control at every stage with high-grade materials and comprehensive performance testing

- Stage-wise inspection

- Premium materials

- Safety compliance

Custom Solutions

Every furnace is engineered to meet your specific metallurgical requirements and production workflow

- Tailored designs

- Flexible configurations

- Scalable systems

Reliable Service

Comprehensive after-sales support with quick response times and genuine spare parts availability

- Pan-India service

- AMC programs

- Technical support

Engineering Excellence in Heat Treatment

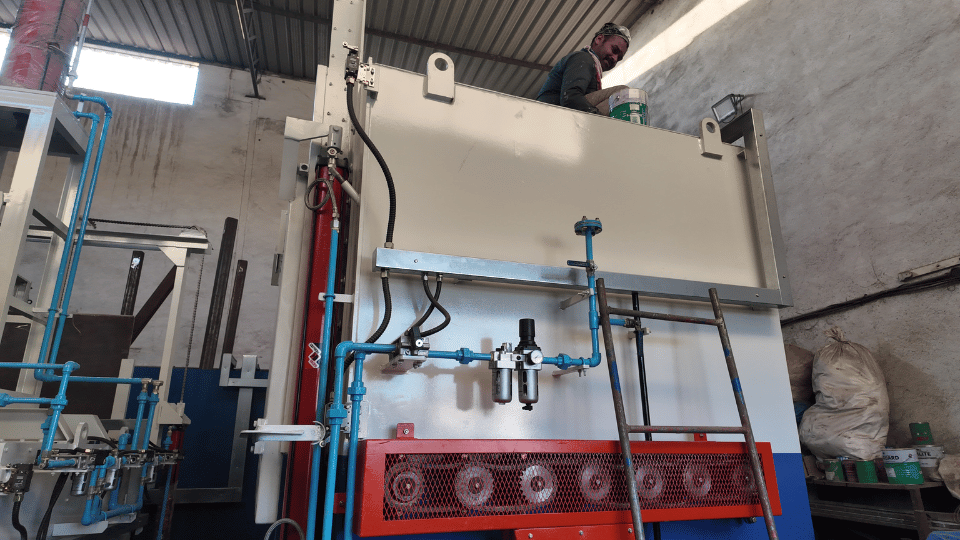

From concept and design to manufacturing, installation, and commissioning, we provide end-to-end heat treatment solutions that meet demanding industrial standards.

Our Customers Say About Us

“Reliable furnaces with excellent performance”

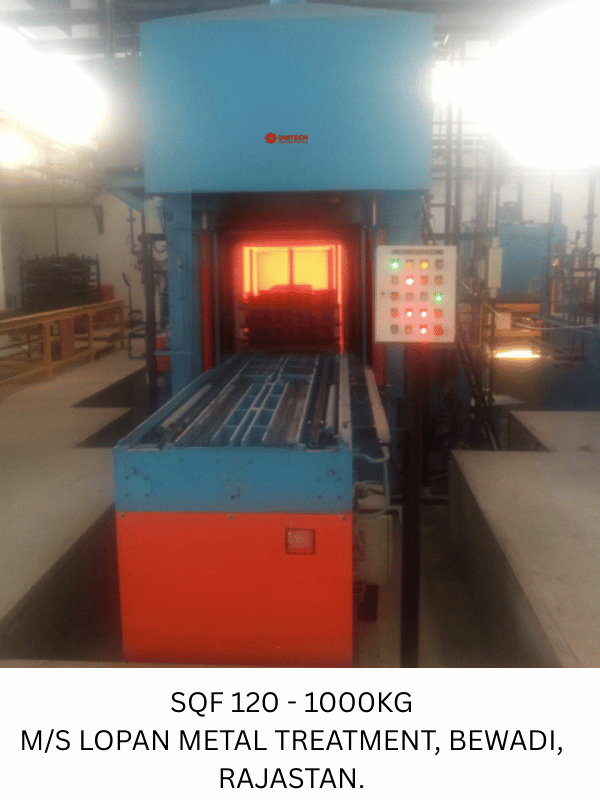

UNITECH ENGINEERING delivered a sealed quench furnace that has been running consistently with excellent temperature uniformity and repeatability. Their engineering approach, build quality, and commissioning support were impressive. A dependable partner for heat treatment solutions.

“Strong technical knowledge and customization”

What sets UNITECH ENGINEERING apart is their deep technical understanding of heat treatment processes. They customized the furnace design exactly to our production requirements and metallurgical needs. Performance and reliability have exceeded our expectations.

“Professional team and timely execution”

From design to installation, the entire project was handled professionally. The team communicated clearly, met timelines, and ensured smooth commissioning. The furnace has been operating flawlessly since installation.